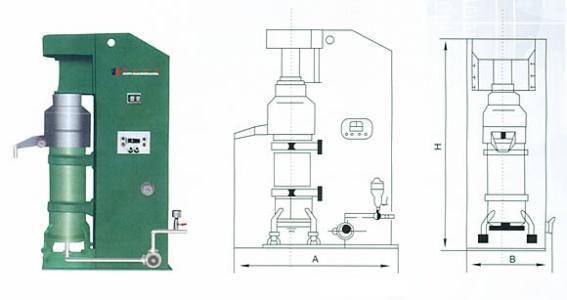

15LVertical Sander

Product Introduction

Ceramic Sander adopts axial force plate grinding structure and is arranged in order. This system overcomes the defect of uneven distribution of grinding media in traditional grinder, so that the grinding media can obtain kinetic energy transmission and high grinding efficiency. It uses double inner holes with forced refrigerator seal, which has good sealing performance. The separation system uses large flow LDC dynamic grid slot type separation equipment, which is not easy to block the feed inlet under large flow conditions, The total area of overcurrent is 0.05-2.0mm, and it can be applied to grinding media above 0.1mm.

The Sander adopts the design scheme of disc type or rod pin type, closed inner wall type. The grinding plates are installed on the mixing shaft in order, which overcomes the defects of the traditional horizontal Sander that the grinding medium is uneven and the Particle size analysis is poor after grinding. Materials enter the grinding chamber under the effect of the feed pump. The design scheme of the channel is to push one end of the connecting flange plate, and the flow of materials and the rolling bearing of the mechanical equipment are opposite to the bottom, This greatly reduces the bearing capacity of the machine seal and improves its service life. During the high-speed operation of the mixing shaft and axial force plate, the compound between the material and the grinding medium generates relative velocity. As a result, the solid particles of the material are dispersed, cut and ground, and separated by the dynamic large flow motor rotor gap through the filtering device to obtain the product.

Precautions for operation:

① For long-term parking, before starting the machine, it is necessary to check if the decentralized disk is stuck by the medium. If the coupling does not rotate, you can use a pump to inject organic solvent. Wait until it dissolves before starting. Do not force the start to prevent damage to the friction plate.

② For long-term parking, before starting the car, it is necessary to check if there is any film coating on the top screen. If there is, clean it with organic solvents to prevent the screen from clogging and causing the roof to fall.

③ In case of "roof fall" of the laboratory Sander, park the car to clean the screen, place the slurry receiving basin, adjust the speed of the slurry supply pump, and restart. Otherwise, the paint slurry may invade the spindle bearings of the machine tool, causing damage to the rolling bearings or damaging the feed pump.

④ Do not start when there is no paint or grinding medium inside the cylinder.

⑤ When cleaning the cylinder section with organic solvents, only rotate the diffuser slightly and intermittently to prevent damage to the components.

⑥ When applying new sand, residue and dirt should be screened. Sand used for Sander shall be cleaned, screened and filled with new sand on time.

⑦ The observation window shall be kept intact to prevent the normal Sander from collapsing and causing safety accidents.